Screen printing frames

Constant innovations make Hurtz a reliable partner: with a computer-aided special programme, Hurtz can define or calculate the most suitable profiles for the screen printing frame for your frame requirements. Our range of screen printing frames is diverse and sorted for your different applications: screen printing frames in standard formats, for the electronics industry, for textile printing and the Hurtz Corner Lock System for large screen printing frames.

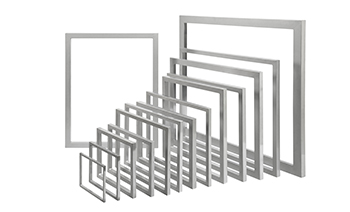

Standard printing Frames

The Hurtz team manufactures standard aluminium screen printing frames in the shortest possible time. Many sizes are kept in stock and can be delivered as quickly as possible in larger quantities. Generally, Hurtz screen printing frames are equipped with a sandblasted adhesive side. Additions for different machine mountings are also no problem for Hurtz!

Dimension: individual taylor made

- welded

- polished

- Adhesive surfaces blasted

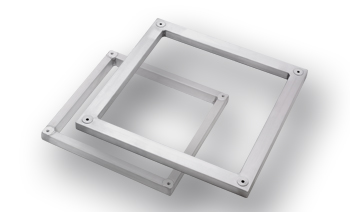

Screen Printing Frames for the electronic industry

Aluminium and stainless steel screen printing frames for the electronics industry are offered by Hurtz, these include:

Solar Frames

- in slope profile

– With inserts

- Support surfaces milled flat

Cast frames

Cast frames

- milled on both sides

- all sides deburred

-individual inserts possible

- for high fabric tensions

Aluminium and stainless steel screen printing frames for the electronics industry are offered by Hurtz, these include:

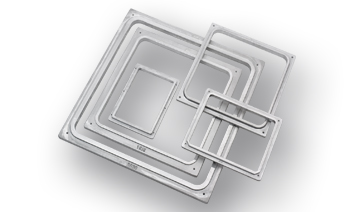

Screen printing frames for textile printing

Screen printing frames made of aluminium are manufactured for textile printing with machine-typical fastening and positioning aids, such as screen printing frames with plastic fitting bushes (for MHM machines), Zimmer stops or Buser tabs.

Dimension: individual taylor made

- with various stops

plastic, steel or stainless steel Positioning aid

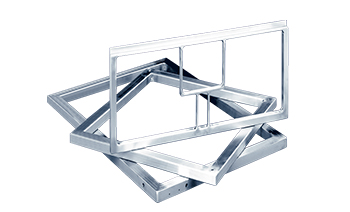

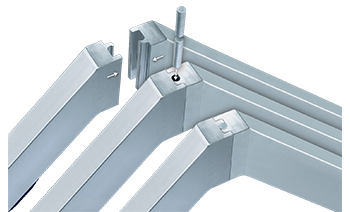

Corner Lock System

Dimension: individual (max. 4x8m)

-maximum stability

– Maximierte Stabilität

Innovative corner lock for maximum strength and favourable transport for large screen printing frames.

The Hurtz Corner Lock System makes industrial screen printing on large surfaces competitive: